No,just because the Canada-Europe Free Trade Agreement(AECG or CETA depending on the Atlantic side is located) doesn’t mean that it exempts you from consolidating the current regulations of the importing country…

Currently, most of my clients contact me to comply with the regulations on labelling standards (in Europe or Canada), and they flabbergasted when I ask them if they have the necessary certifications regarding quality …

However, this is not a subject to be taken lightly … As proof, look at what passions have been unleashed, in some European countries, against the signing of the agreement.

These events of all kinds have demonstrated the importance of Europeans’ attention to food security and their (real) fear of eating only Canadian ‘hormone beef’.

This left me speechless on the level of ignorance of my fellow citizens …

“It was time to shed light on all this!”

Because YES! Regardless of the country in which you export, you must submit to ALL the regulations in force in this country.

Nor is it because you have found a customer or distributor willing to market your products that the customer assumes responsibility for marketing the product…

“YOU STAY THE ONLY PRODUCT RESPONSABLE SOLD”

This quite complicates things… but that’s why we can go with you!

Internationally recognized repositories

The only internationally recognized quality repositories are:

- HACCP

- Standards: ISO 22000 – ISO 14001 – ISO 9001 and so on

- GFSI: IFS – BRC – FSSC 22000

All have a different level of requirements that increases the closer we get to the GFSI.

HACCP

HaCCP is, unlike all others, arisk-controlmethodology that the company must implement.

It is therefore unique to each company depending on its configuration, its equipment, its personnel, etc.

It is therefore impossible to transpose a model from one company to another since no company is strictly identical to another… You’ll have to do your own analysis.

Moreover, unlike other repositories the HACCP is not certifiable … even if you find many companies willing to issue you a HACCP “certification.”

Your method can be evaluated by a certifying body but not certified!

Subtlety is great because it means that a “certificate” would have no legal value and would not be recognized anywhere in the world.

A HACCP method cannot be certified !!!!

So you don’t have to spend money on an audit that won’t do you any good.

ISO 22000

ISO 22000 overcomes this problem because this standard can be certified.

This food safety management system not only incorporates the HACCP principles,to which it adds food safety management.

This novelty means that it can be used by all players in the food chain: producers, manufacturers, processors, transport operators, warehousing, distribution but also manufacturers of equipment, packaging, cleaning products, etc.

If you want to get a certification at all costs, this is the simple one!

FSSC 22000

The FSSC 22000, for Food Safety System Certification 22000, is an international private certification device that integrates ISO 22000, while taking up other requirements not covered by this standard (food fraud and food defense in particular).

It is applicable to the agri-food (manufacturing and processing) and packaging sectors.

The objective of this scheme is to supplement the requirements of ISO 22000 in order to be recognized by the Global Food Safety Initiative(GFSI). A good alternative, therefore, if one wishes to be recognized by the GFSI without embarking on the long and complex steps of the BRC or the IFS.

IFS or BRC

The British Retail Consortium (BRC), of Anglo-Saxon origin and theInternational Featured Standards (IFS) Food of Franco-German origin, are private repositories, developed by and for supermarket.

The complexity of setting up these repositories comes from the fact that they do not apply to all players in the field, but are divided into as many repositories dedicated to each group (e.g. IFS for transport, IFS for producers, etc.).

In addition to results obligations, the BRC and the IFS set obligations of mean. They are therefore much more restrictive to apply.

Finally, BRC and IFS incorporate provisions to prevent malice (food defense) or manage issues of authenticity of raw materials (food fraud)

BRC and IFS are both recognized by the Global Food Safety Initiative (GFSI) and may be certified by a certifying organization.

Which repository to choose?

It all depends on your marketing strategy.

It’s pretty simple! Itis enough that you determine to whom you want to sell your product and how.

For example, the Large European Distribution Groups require that an IFS or BRC quality repository (depending on the country) be established for all their private label brands.

So if you want to sell under your own brand, no problem! You don’t need it.

Beware, too, if your product enters the composition of a private label OR if your distributor wishes to sell to the Retail …

However, as certifications have become a competitive argument to stand out from your competitors, it is sometimes a good idea to put in place a quality system in order to win new contracts or contracts.

We can support you in the distribution strategy of your products and advise you on the best repository to set up. Contact us !

Rules in Europe

Basic requirements

There are many rules to be followed before they can be exported to Europe. But one of the most restrictive, because of the most expensive, is compliance with the rules ofhygiene and food safety; the minimum required being the HACCP.

The European Regulation 852/2004 is very clear on this subject:

“Companies in the food sector […] must apply the principles of the Risk Analysis System and Critical Points for Their Control (HACCP), introduced as part of the Codex alimentarius”

This measure also applies to all imported products:

“Food imported into the EU […] must meet EU standards … »

It is impossible to sell a product in Europe without it!

WARNING !!!

With the product traceability system (another European regulation…), you could be indirectly affected (even if you do not sell in Europe) !!! To the extent that one of your customers wants to sell in Europe. Then the same rules would apply to your products…

Same for the ingredients!

If your products are ingredients of products sold in Europe, it also concerns you

The particular case of private labels

Distributors, by branding the products sold, bear all the responsibilities of food producers. As a result, they had to conduct audits of all food production and processing sites to ensure compliance. A titanic job!

Starting in 2000, to harmonize the requirements and avoid too many controls, European distributors imposed the basic IFS and BRC repositories for their private label.

Meanwhile, most French and German distributors stipulate that IFS certification is a prerequisite to be included in the list of their suppliers.

Rules in Canada

Basic requirements

Since 2005 and until now, only federally licensed meat and poultry processors have had an obligation to apply a HACCP method.

However, with the implementation of the Safe Food for Canadians Regulations, which will come into force on January 15, 2019, any company whose annual turnover is greater than $100,000, will be required to put in place a a Preventive Control Plan (PCP).

“The licensee is required to establish, maintain and maintain a written preventive control plan . . . for any activity covered by its licence to any food or animal for human consumption”.

The same is true for imported products (with a few exceptions):

“The food that is imported must have been manufactured, packaged, stored, packaged and labelled in conditions and in a manner that provides at least the same level of protection as sections 47 to 81.”

The Food Safety Improvement Program (PASA) is a type of preventive control plan (PCP) created by the Canadian Food Inspection Agency (CFIA).

It is based on the HACCP, to which it adds “pre-programs” that the institution must implement before developing its HACCP plans. That is why we are commonly talking about HACCP-PASA in Canada, not HACCP.

This PCP is an example provided by the government, with no obligation to use.

“You remain free to use any document of your choice, as long as it allows you to get the results of a PCP”

HACCP-PASA or other repository?

As it is a document created by the CFIA, it is only valid in Canada and has no international value.

Admittedly this is a minimum required, but why in this case do not use an internationally recognized repository rather than a document recognized only in Canada … ???

Compliance deadlines

If you hold an accreditation that will expire before the RSAC comes into force, you can have your accreditation renewed under the old Act. It will be valid until its expiry date even if the license date precedes the expiry date of your accreditation.

For all those whoseapproval expires after the RSAC comes into force,you will have to comply with the new rSAC obligations on the following schedule:

- Dairy products, eggs, processed fruit and vegetable products: 15 January 2019

- Fish: January 15, 2019

- Animals for human consumption and meat products: 15 January 2019

- Fresh fruit or vegetables: January 15, 2020

- Honey and maple products: January 15, 2019

- Unprocessed foods for use as grains, oil, legumes, sugar or beverages: 15 July 2020

- Food additives and alcoholic beverages: not required

- All other foods: July 15, 2020

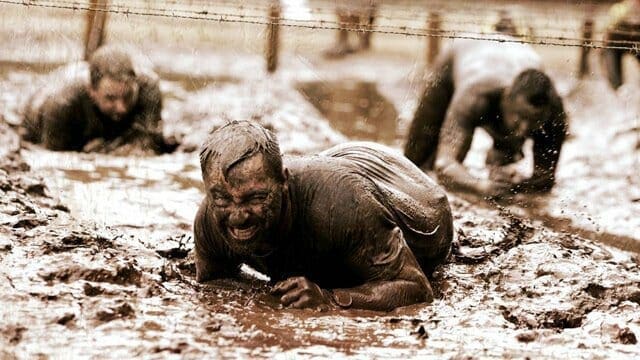

Getting up to standard: a fighter’s journey?

All this seems very complicated and you are already lost just reading this article? Don’t worry, we’re here to help. Of course we won’t let you down…

Whether you need to export to Canada or Europe, or simply comply with the new legislation soon to be in place, we can advise you to determine best which repository you need to put in place, according to your strategy. national or international development.

And the good news for Canadians is that:

“Subsidies exist in Canada to implement certification!”

We are already presenting files for several of our clients …

Diagnosis

The first step is to make a diagnosis of your institution to determine which quality system you have. Our partner will travel to your home (wherever you are in the world) to study your manufacturing-transformation processes, installations, etc. for 2 to 3 days.

At the end of these 3 days, he will tell you:

- The most relevant repository to use

- an Action Plan of things to put in place, with a retro-planning compared to a certification target date

- The choice of the certifying body intervening in your country and recognized in the destination country for companies wishing to export

Of course, international rules prevent, for ethical reasons, that the consultant setting up the quality system, is the certifying body.

The accompaniment

Since the implementation of a quality system is a long process, it takes about 9 to 18 months to obtain its certification. So patience!

So it’s best that you anticipate that,if you have a timetable for 2020. !

During this period our partner will carry out a mission of advice to explain the necessary points and correct the actions carried out by the company.

During these field missions, in the company, he will carry out mini-audits to validate progress, feed the action plan and build the internal audit schedule necessary for all standards.

Depending on the needs, he will also train the staff concerned on HACCP, hygiene rules, VACCP, internal audit, controls, standards chosen….

Certification

Finally, with D-Day arrived, the pre-selected certifying body will conduct the final audit and issue your certificate.

Wherever in the world you want to sell your products, many local laws and regulations must be respected. I have tried here to give you a picture of the quality rules that apply in Europe and Canada, as well as internationally recognized benchmarks, and therefore I strongly advise you to apply.

Nevertheless, this is only the tip of the iceberg …

Many other regulations must be respected such as traceability, packaging, labelling, organic products, genetically modified organisms, food contaminants, etc.

There are more than fifty of them in Europe …

In the event of non-compliance, the exporter will have its product declared “non-compliant” and therefore illegal. He will then have to withdraw it from the market. In the most serious cases, it may have to carry out a recall, with the disastrous economic consequences that this entails, since it can be extremely difficult to find all the products already sold.

All this not to mention the criminal (up to imprisonment) and administrative sanctions that he risks …

So don’t hesitate to consult us to be “in good standing”!

0 Comments